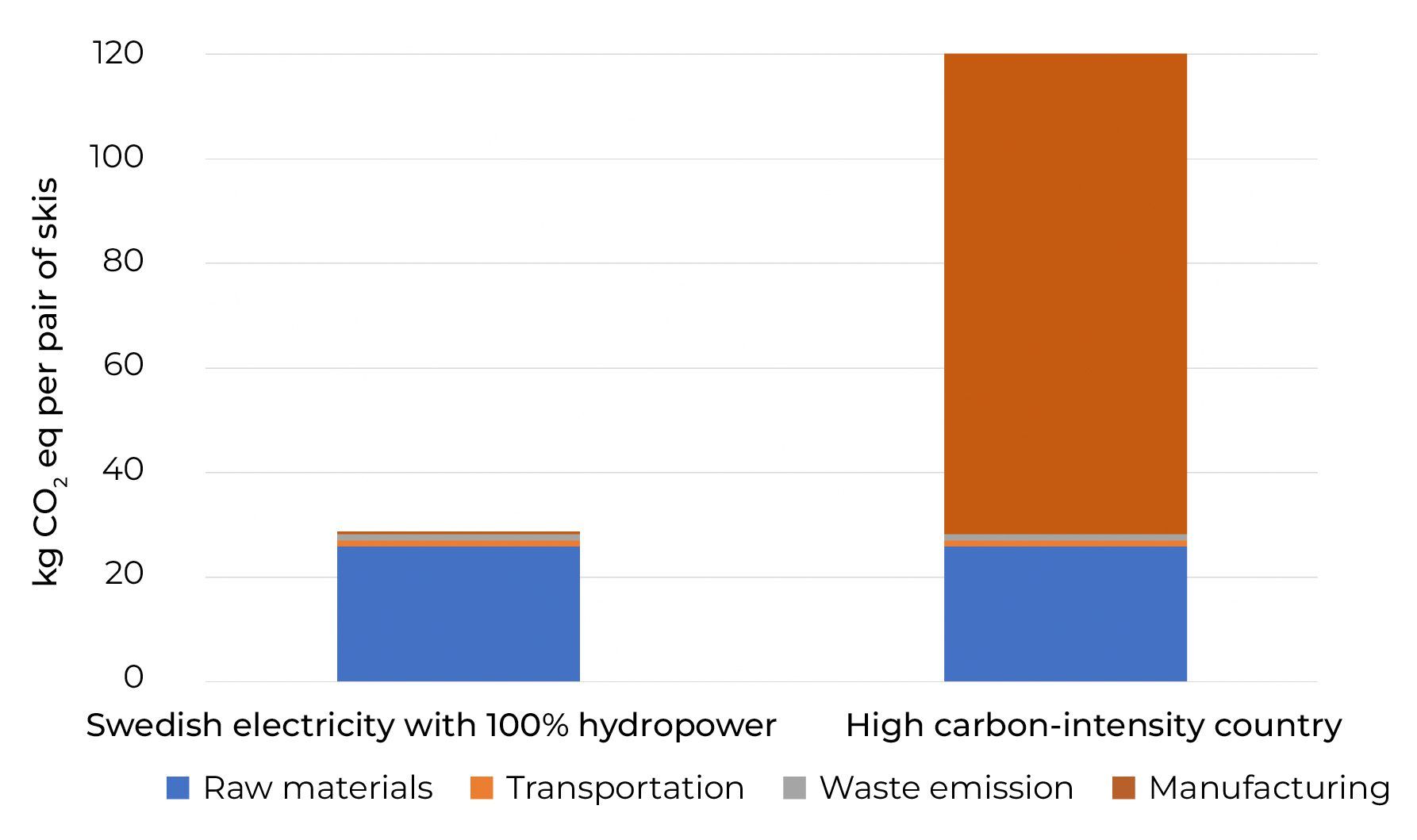

Together with RISE – the Research Institutes of Sweden – we have identified the energy mix as the single biggest factor in the environmental footprint of ski production.*

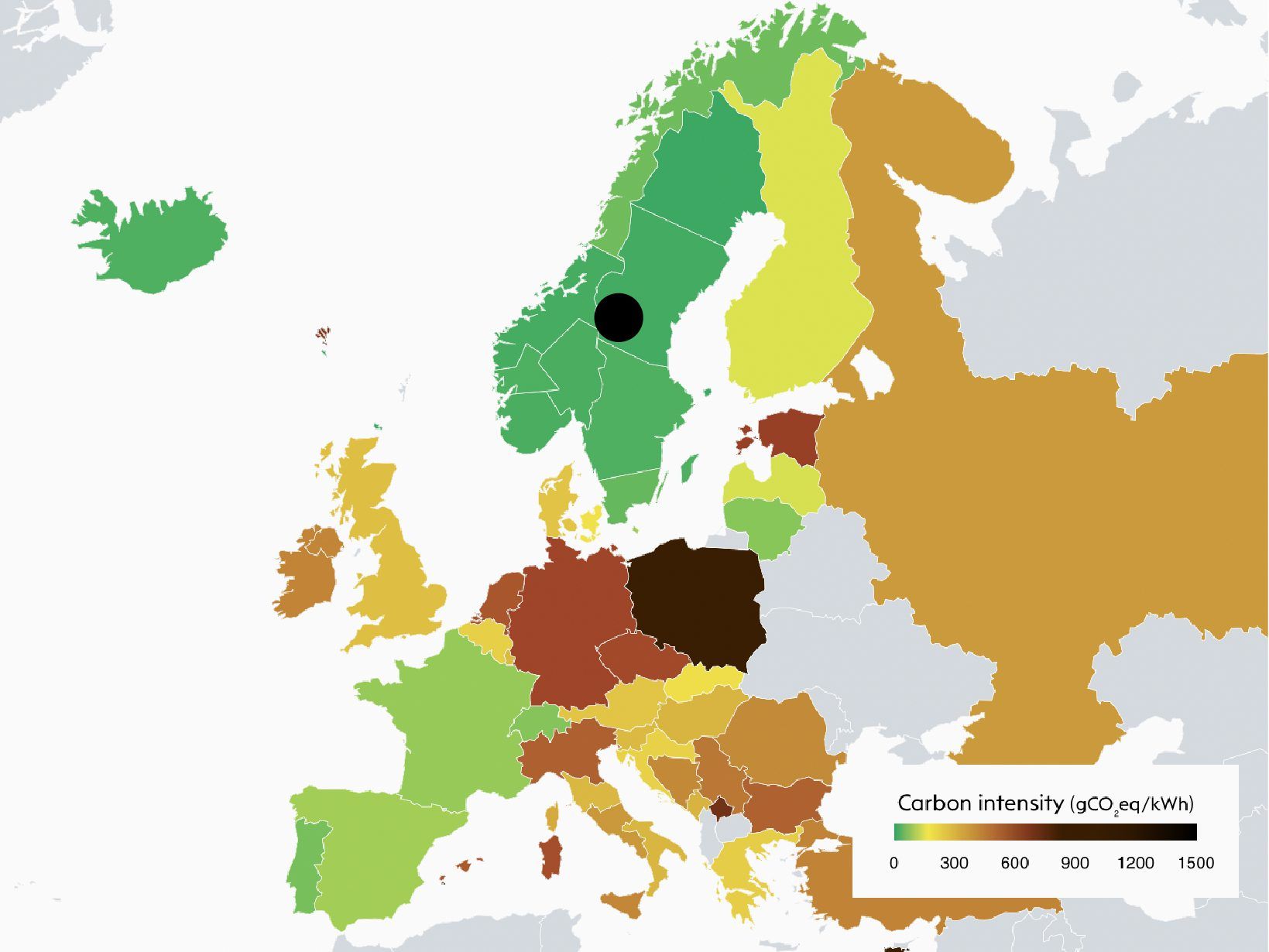

North central Sweden, where we’re located, is dominated by 100% renewable and 100% fossile-free, local, hydro power. With a five-year average of 16 g carbon intensity per kWh (gCO2eq/kWh), our region is the lowest carbon emission consumer per kWh in the world.** Compared to other European ski producing countries such as Germany, Austria, Switzerland, France, Poland, Slovenia, Spain and the Czech Republic, with an average five-year carbon intensity level of 352g per kWh, the difference is substantial.**